Dụng cụ sửa đá mài

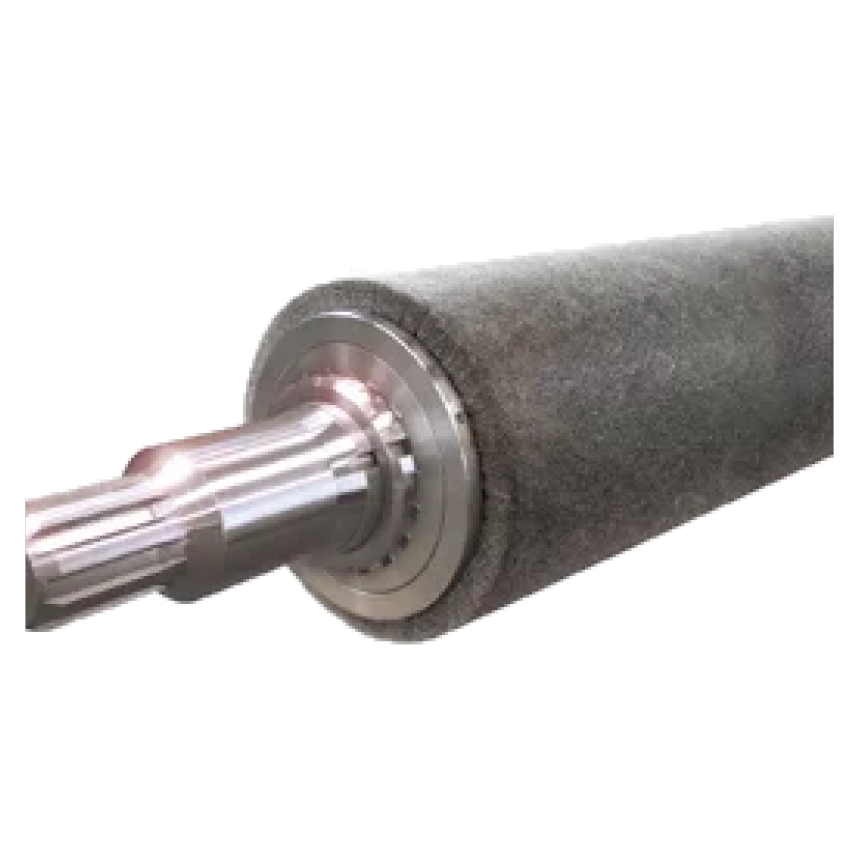

Giới thiệu về roller dresser sửa đá mài bánh răng Roller dresser sửa đá mài bánh răng hay còn gọi là gear dresser là dụng cụ sửa bề mặt đá mài chuyên dụng dùng để gia công mài chính xác bánh răng. Mài bánh răng là một trong những phương ...

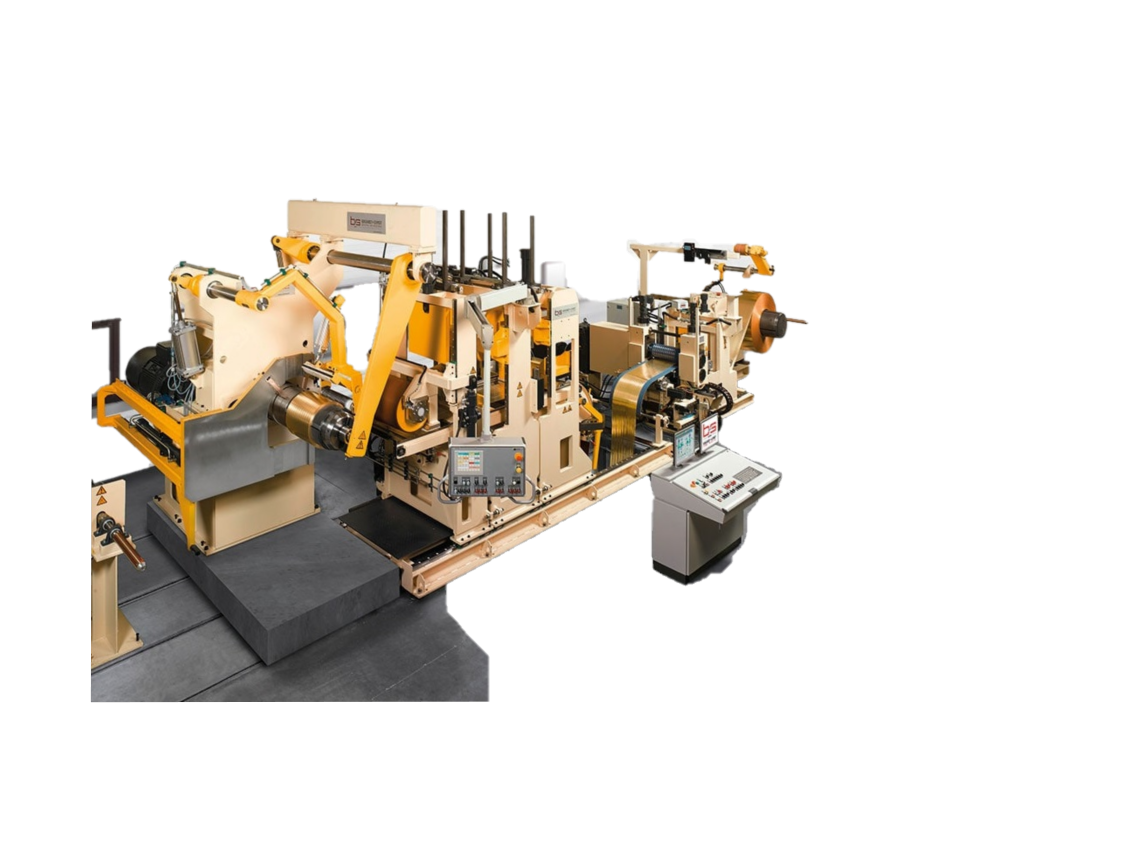

Hệ thống sửa đá tự động Hệ thống sửa đá tự động bằng chương trình CNC cung cấp sự linh động và có thể ứng dụng trong shop gia công nhỏ và sản xuất hàng loạt. Innsotech cung cấp hệ thống sửa đá tự động cho nhiều quy trình và ...

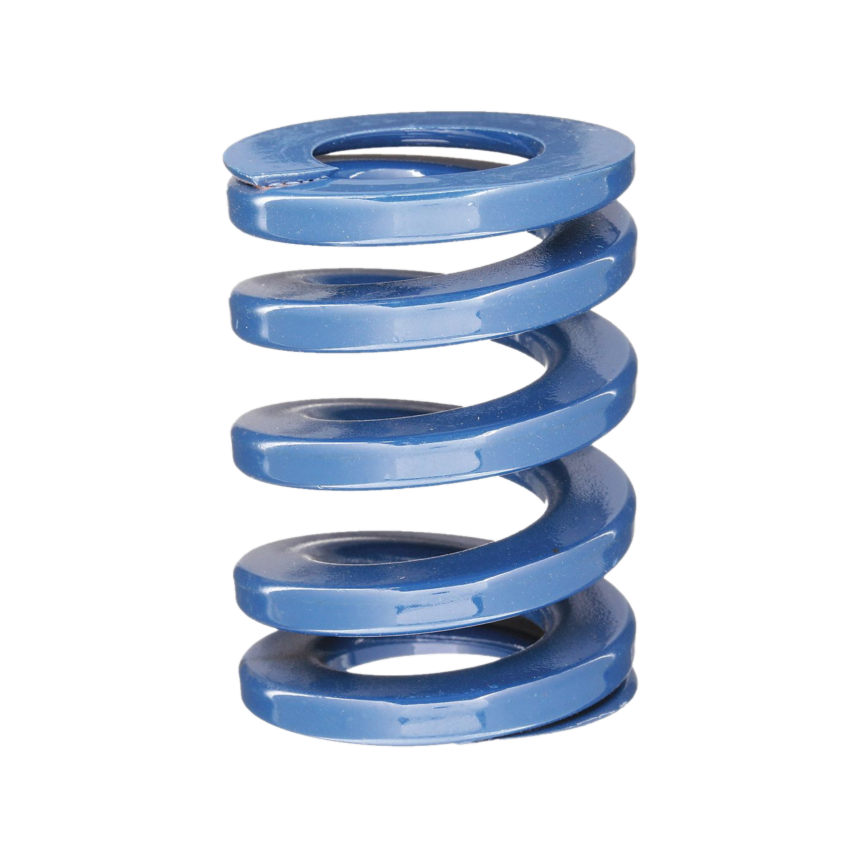

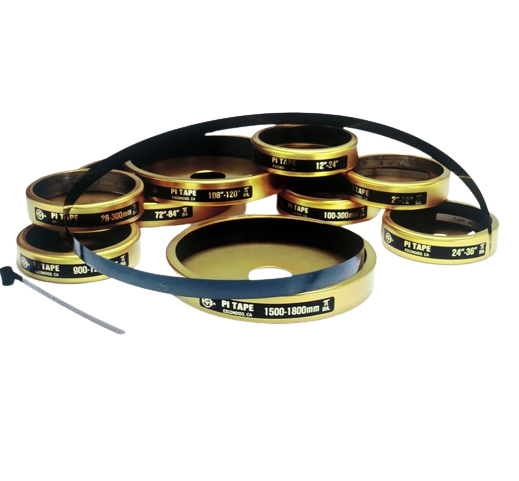

Roller Dresser Thông qua việc chỉnh sửa độ tròn và làm sắc lại bề mặt đá mài theo đúng hình dáng ban đầu, roller dresser duy trì tính hiệu quả, độ chính xác và duy trì năng suất cũng như là chất lượng trong sản xuất hàng loạt. Roller dresser ...

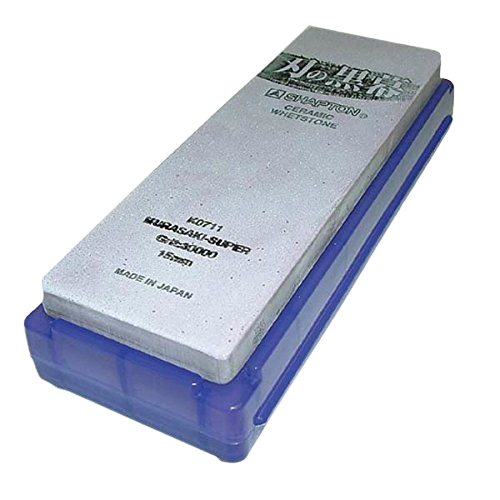

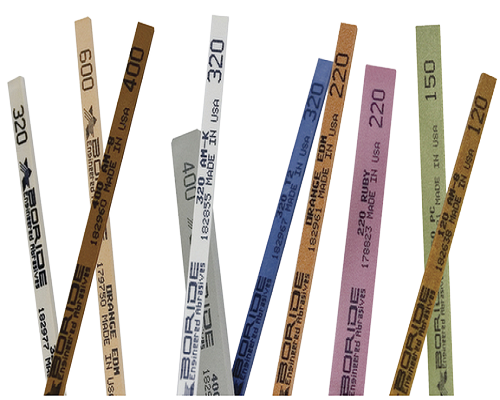

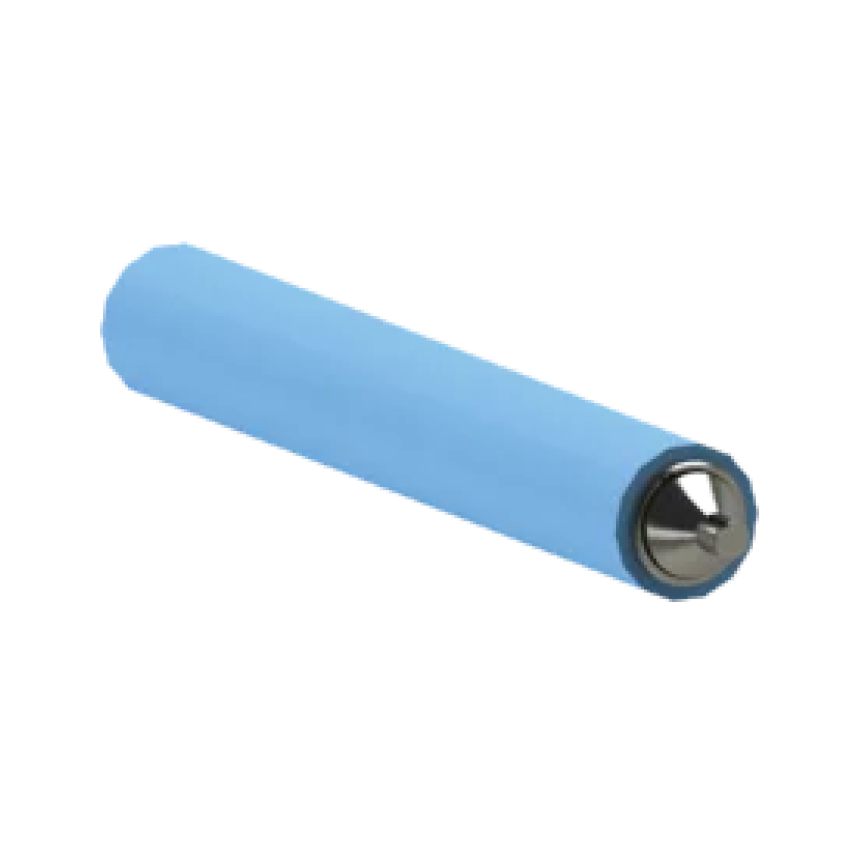

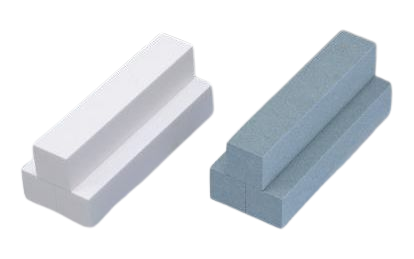

Thanh sửa đá (dressing stick) dùng để chỉnh lại độ đồng tâm của đá, làm sạch chất cặn bẩn, phoi và chất keo còn bám lại trên bề mặt đá mài CBN, đá mài kim cương, làm vỡ kết cấu keo để các hạt mài bên trong thoát ra và giúp cho bề mặt đá mài CBN, đá mài kim cương sắc trở lại để có thể tiếp tục mài cắt vật liệu.

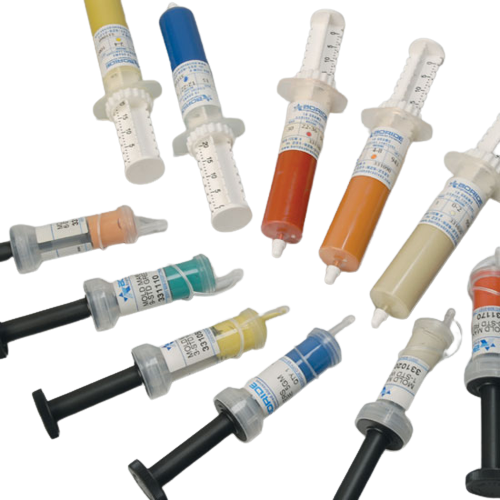

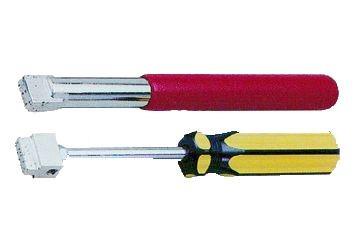

Đầu sửa đá mài cầm tay (Hand Diamond Dressers) dùng để sửa các loại đá mài gắn trên máy mài cố định nhỏ, máy mài hai trục để mài lại dao cụ, mài chi tiết bảo trì, bảo dưỡng cơ khí và ngành rèn, ...

Mũi sửa đá có đầu mài kim cương (impregnated diamond dresser or bond dresser) được sử dụng để sửa đá mài trụ ngoài, đá mài vô tâm và cả đá mài phẳng. Mũi sửa đá có đầu mài kim cương ngày càng được sử dụng phổ biến vì chi phí không quá cao nhưng lại có hiệu quả sửa đá cao, đặc biệt là các loại đá mài có bề dày lớn.

Thư viện thông tin

Nếu quý khách có thắc mắc, ý kiến phản hồi hay đóng góp xin vui lòng liên hệ hotline 02866848386 hoặc gửi email tới sales@innsotech.com.vn

84938 333 755

84938 333 755

Chat Zalo

Chat Zalo

Chat Messenger

Chat Messenger