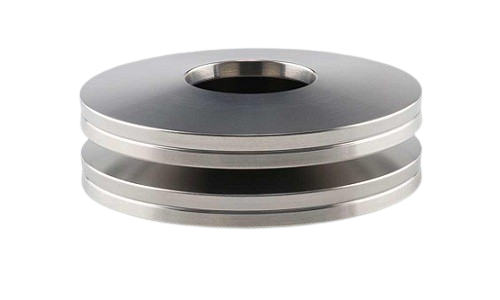

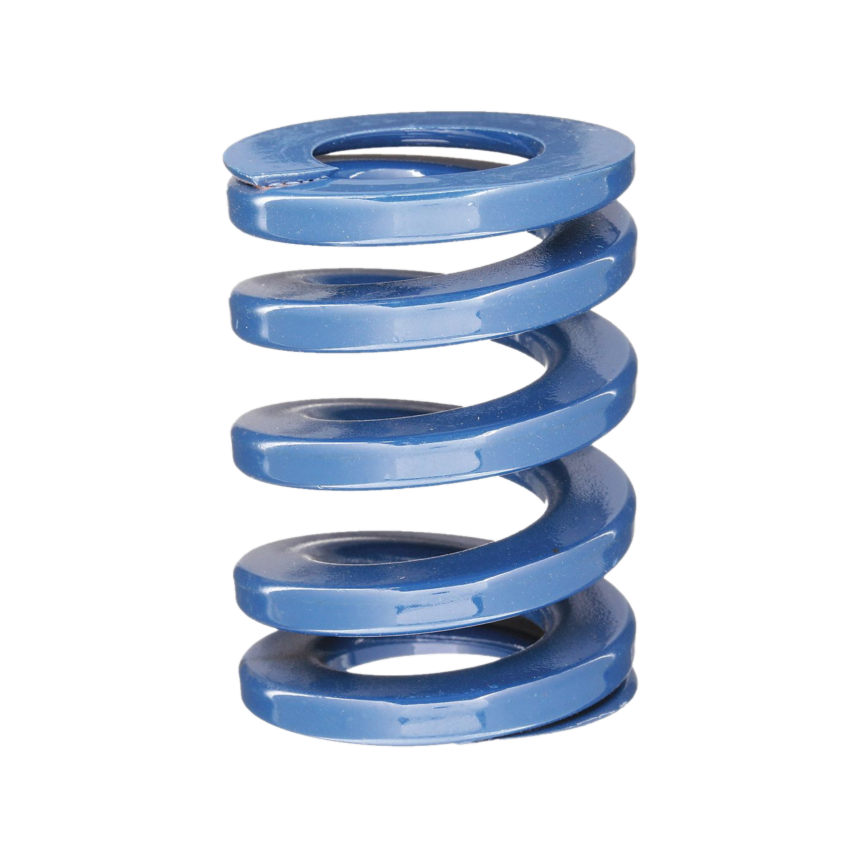

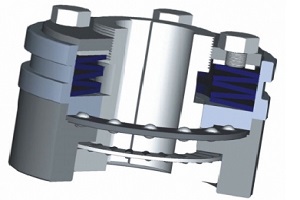

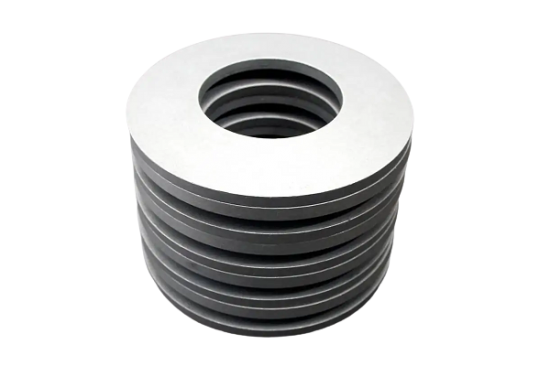

High temperature disc spring made of high temperature (Cryogenic) resistant materials as Inconel 718, 750, these disc springs are applied for high temperature and cryogenic from -200 °C to +500 °C) environments. High temperature disc spring (Cryogenic disc spring) are widely used in Valves, Heat Exchangers, Boilers, Industrial Furnaces and Ovens, Cryogenic Technologies, Special Chemical circumstances, etc..

High temperature disc springs are designed and manufactured according to DIN2.4668 & DIN2.4669.

Application

High temperature disc spring (Cryogenic disc spring) are widely used in Valves, Heat Exchangers, Boilers, Industrial Furnaces and Ovens, Cryogenic Technologies, Special Chemical circumstances.

Technology

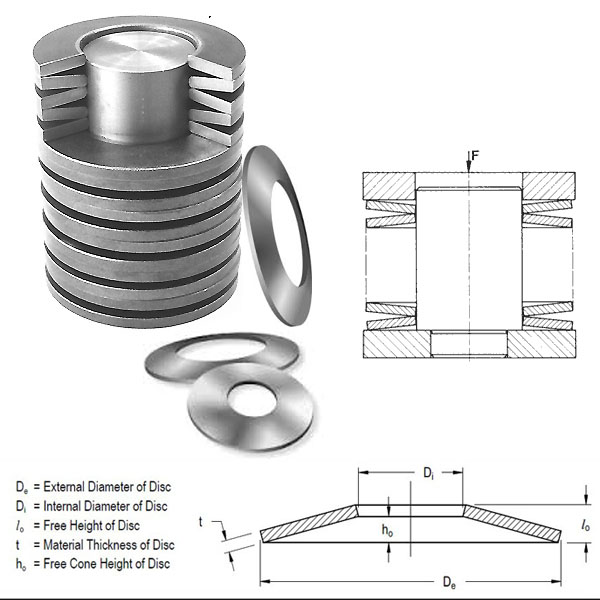

The high temperature springs are vastly ductile and exhibit very high fatigue strength. The lower tensile strength and adverse elastic limit – tensile strength ratio are important when designing disc springs made of high temperature material. If ignored, a high degree of setting loss is potential. An upper operating temperature limit is not viable to indicate and the overall spring height lessens under load due to creep.

The tangible level of creep is a function of temperature, time and stress.

For example, a disc spring can be used at higher temperatures if either a lower load is applied or the duration at the higher temperature is minimal.

Classification

Disc springs produced with thermally stable materials can be used at temperatures approximately 150 °C higher than those acknowledged in. High temperature materials generally have long lead times from the steel mills and are typically very expensive. The most popular high temperature materials are Inconel 718 and Inconel 750.

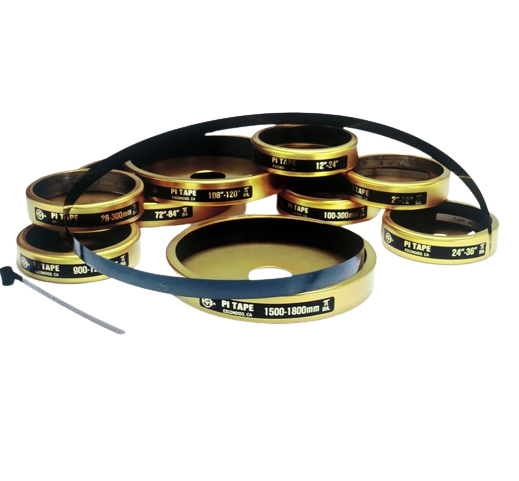

Specifications

-

Kích thước:The max thickness is 8mmVật liệu lò xo:Inconel 718, Inconel 750Tiêu chuẩn:DIN2.4668, DIN, 2.4669

Contact info

-

Hotline hỗ trợ028 66 84 83 86

-

Thư viện media

-

Tư vấn mua hàng0938 333 755

Catalog

Related news

Products in the same group

Thư viện thông tin

84938 333 755

84938 333 755

Chat Zalo

Chat Zalo

Chat Messenger

Chat Messenger