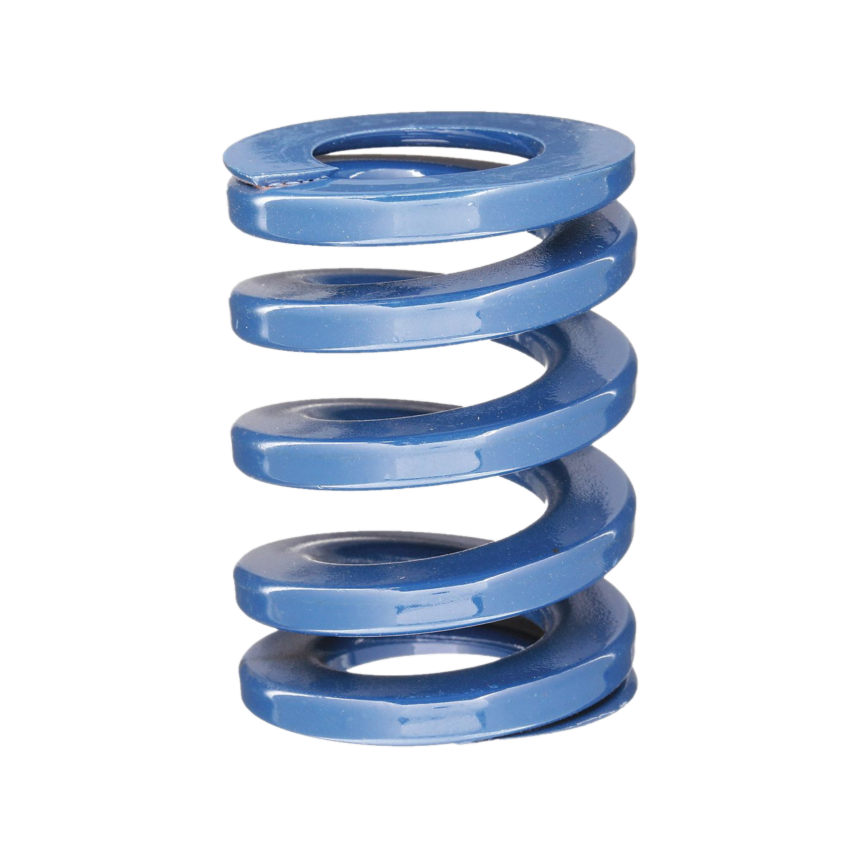

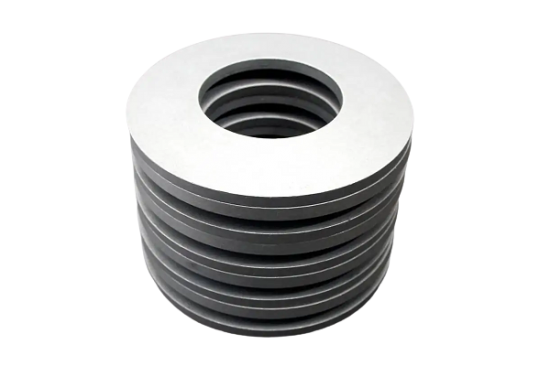

Mubea is able to offer our Generation II disc springs technology. Generation II technology allows the disc springs to operate at higher stress levels than standard Belleville disc springs, providing higher durability and or reduced overall size.

Mubea generation II disc springs are chosen for application with high demanding on spring lifetime, compact working space or heave working conditions where the conventional standard disc springs are not suitable.

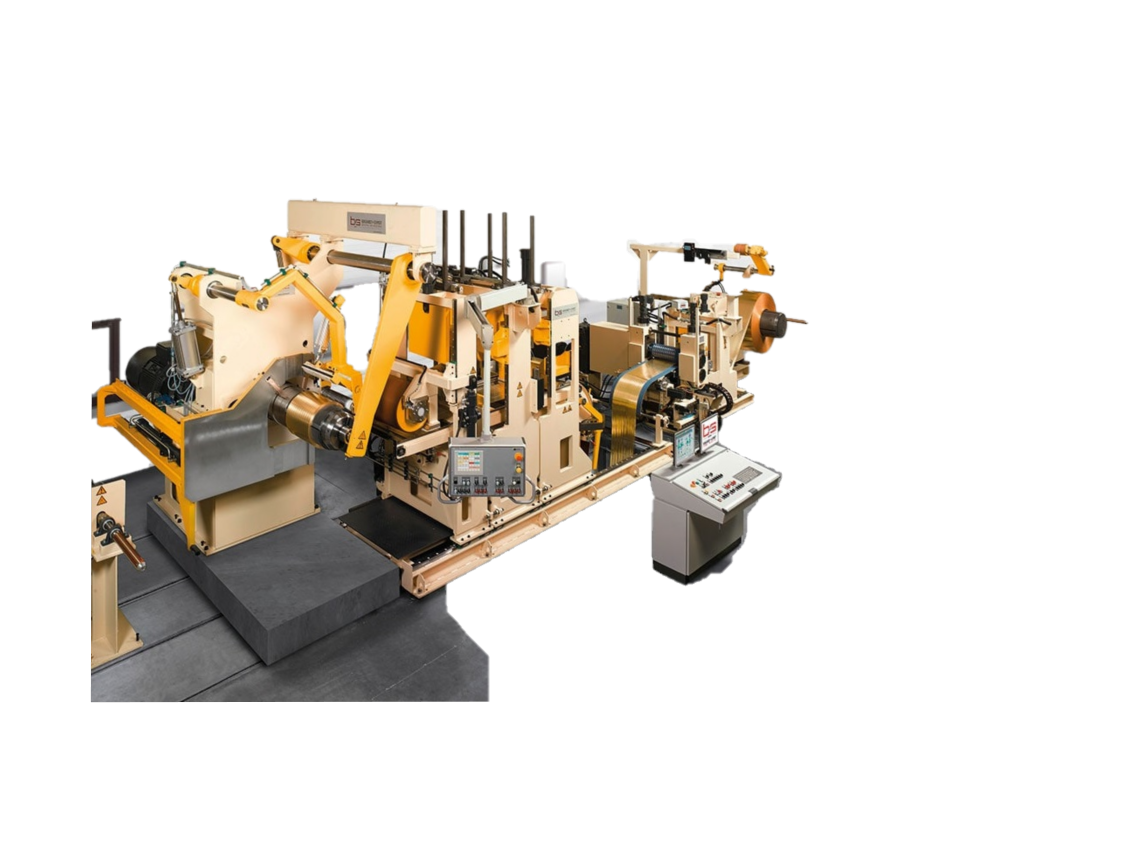

Application

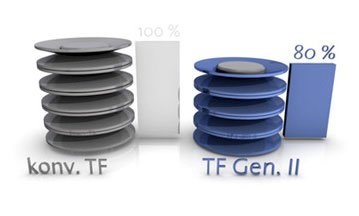

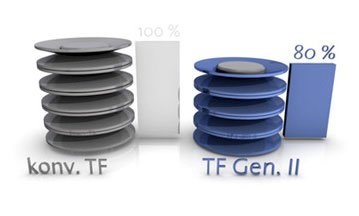

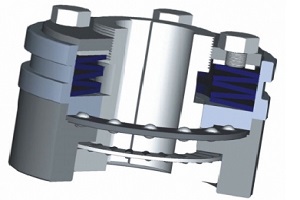

Whether it is increased fatigue life or an overall system size reduction that is desired, Mubea Generation II disc springs are able to offer significant improvements over the current Belleville spring technology. Generation II springs can extend fatigue lives up to a factor of 10 times when compared to standard Belleville springs. If size is the constraint, by using Generation II technology the outer diameter of a standard Belleville springs can be reduced by up to 10%. If increased stroke is the target, travel of an individual Belleville spring or Belleville spring stack can be increased by as much as 40%. If overall assembly space needs to be reduced, Generation II technology allows for a reduction of total required assembly space of up to 20% over the standard Belleville spring line. By utilizing one or a combination of the advantages listed above, Generation II disc spring technology can be used to create an overall system advantage by reducing system size, weight, and cost.

Product features

Mubea’s Generation II disc springs offer a number of distinct advantages over the current Belleville spring lines. These advantages include:

- The lifetime can be increased up to 10 times (see picture)

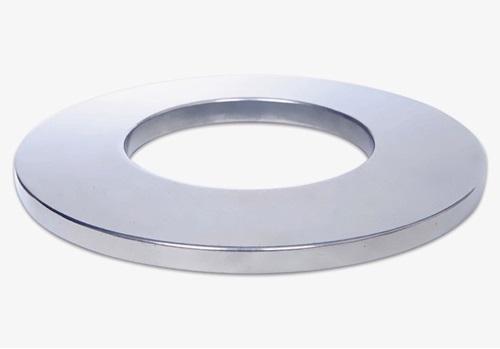

- The outer diameter can be reduced up to 25% (see picture)

- Increased stroke (see picture)

- The installation space can be reduced up to 33% (see picture)

- Overall system advantage (see picture)

Specifications

-

Kích thước:Customized design for each specific requirementVật liệu lò xo:Special steel from Mubea R&DTiêu chuẩn:Mubea standard

Contact info

-

Hotline hỗ trợ028 66 84 83 86

-

Thư viện media

-

Tư vấn mua hàng0938 333 755

Catalog

Related news

Products in the same group

Thư viện thông tin

84938 333 755

84938 333 755

Chat Zalo

Chat Zalo

Chat Messenger

Chat Messenger