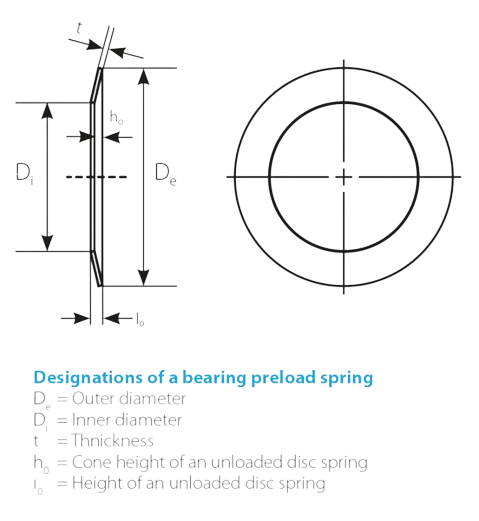

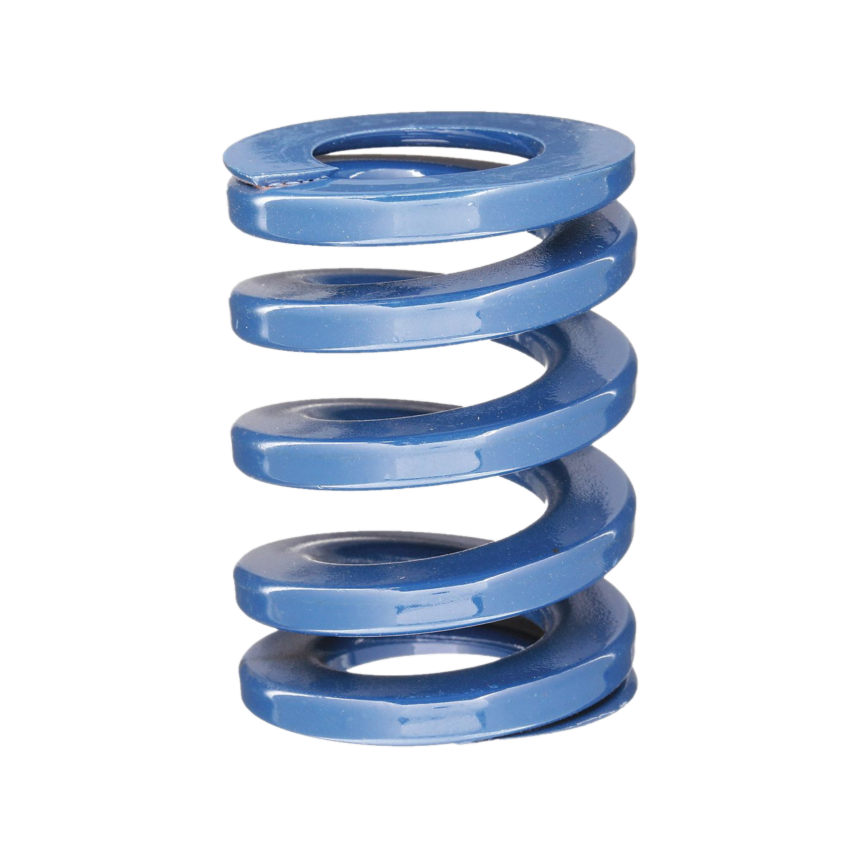

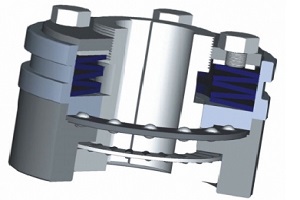

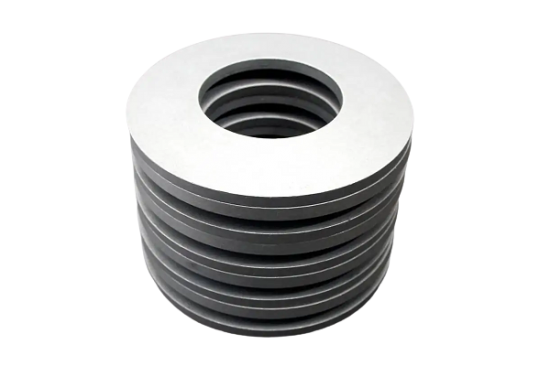

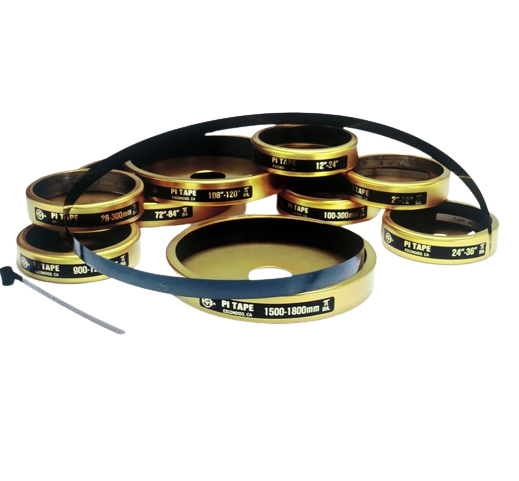

Disc spring for ball bearings, also be known as ‘’Bearing Preload Disc Spring’’, they are assembled with the radial ball bearings, act as a compensator of thermal expansions during their working. Axial preloading of bearing with Ball Bearing Disc Spring extends the bearing life and eliminates excessive running noise. One or more Disc Springs can be used. In most cases the outer race of the ball bearing is preloaded with the Disc Spring. In some cases it is desirable to preload the inner race. The recommended preload is achieved when the disc is deflected to 75% of the free conical heights (ho). The ho/t ratio is designed so that the spring load remains nearly constant for a large deflection range. Tolerance builds up and variations resulting from expansion can be accommodated without a significant change in preload. Disc Springs may also be used to preload seals, packing, clutches and other machine elements.

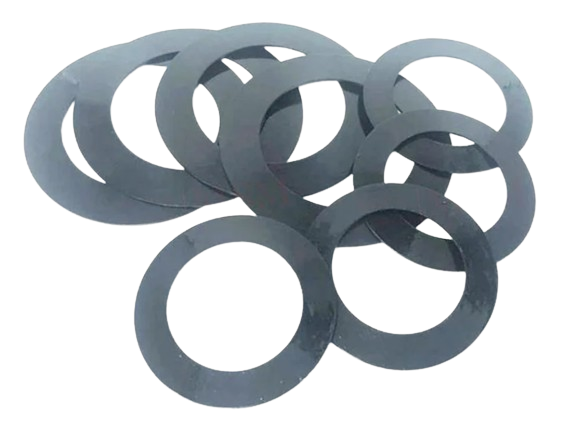

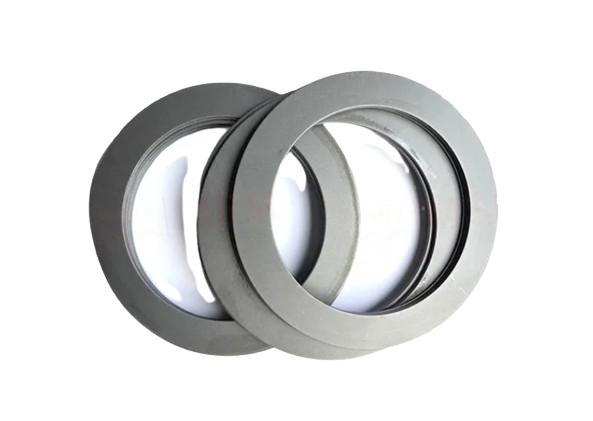

Plain Disc Springs for Ball Bearing:

Plain disc springs assist in maintaining positioning accuracy of the bearing (with no end play) and also minimize vibration and shaft deflections. Correct preloading will also increase bearing rigidity and negate excessive running noise. Plain Ball Bearing disc springs with high force, low deflection and pronounced regressive spring characteristics are for backlash compensation, silencing and protection of ball bearings A note of caution however when considering columns of these disc springs. A ratio of cone height/thickness in excess of 1.50 could cause springs to invert and the column to collapse. Outside diameters OD ranging from 9.8 – 358mm (0.386″ – 14.1″)

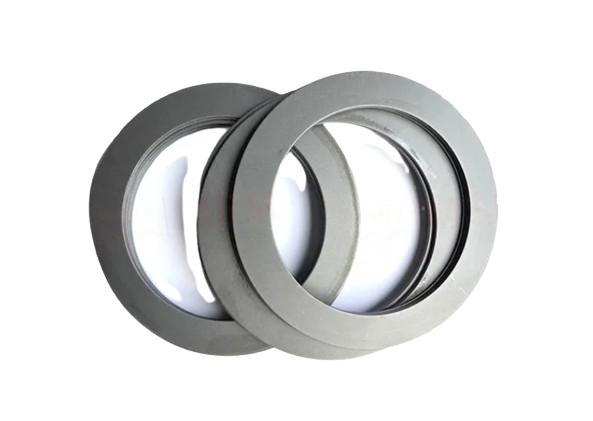

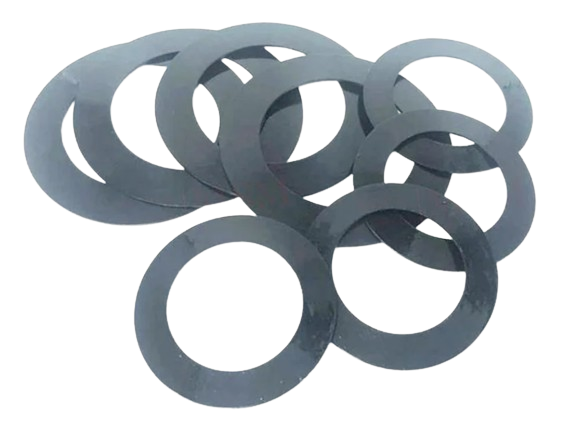

Slotted Disc Springs for Ball Bearing:

This range of slotted disc springs have a slotted inside profile which gives a different force/deflection profile to plain disc springs. Slotted disc springs with low force and large deflection characteristic are increasingly required for use with small size ball bearings. In cases where higher spring forces are required, the Disc Springs can be stacked in parallel for corresponding factors of two or more. A note of caution however when considering columns of these disc springs. A ratio of cone height/thickness in excess of 1.50 could cause springs to invert and the column to collapse. Outside diameters OD ranging from 9.8 – 94.5mm (0.386″ – 3.72″)

Application

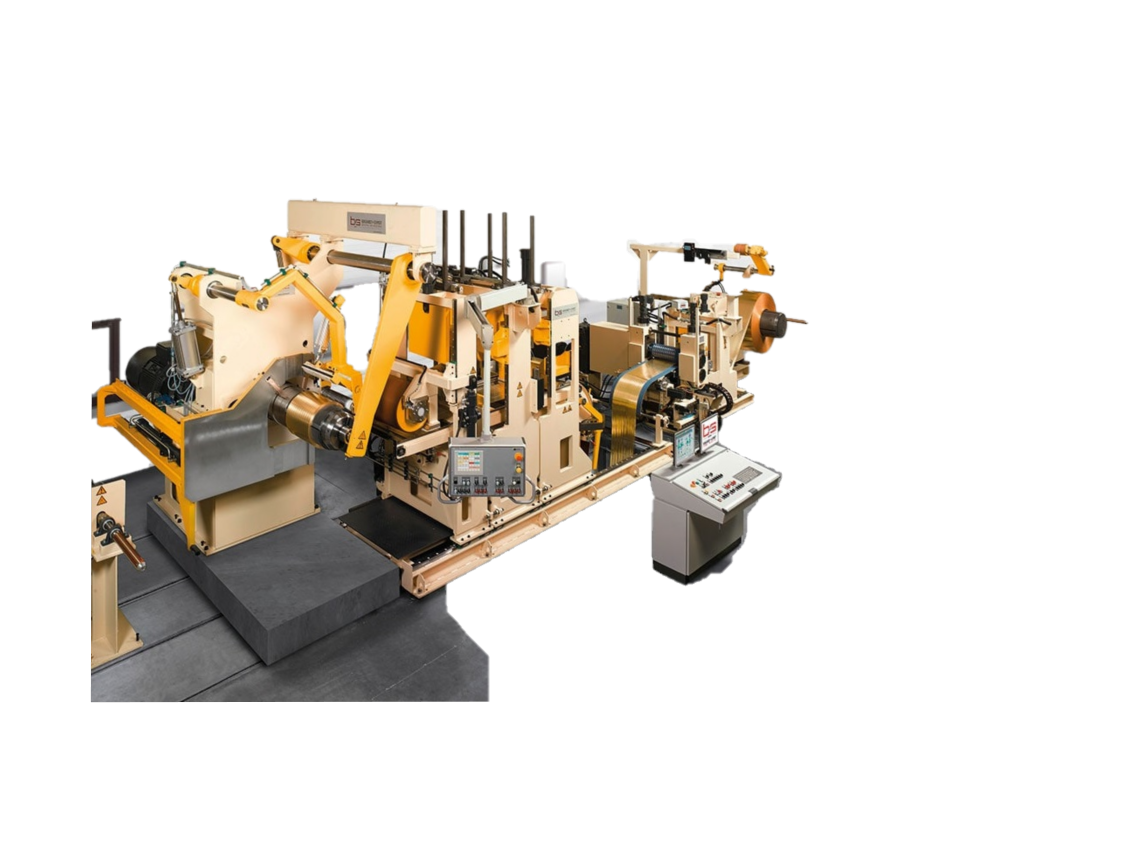

Ball bearing disc springs find applications in various mechanical systems where controlled movement, load distribution, and low friction are crucial. Some common applications include:

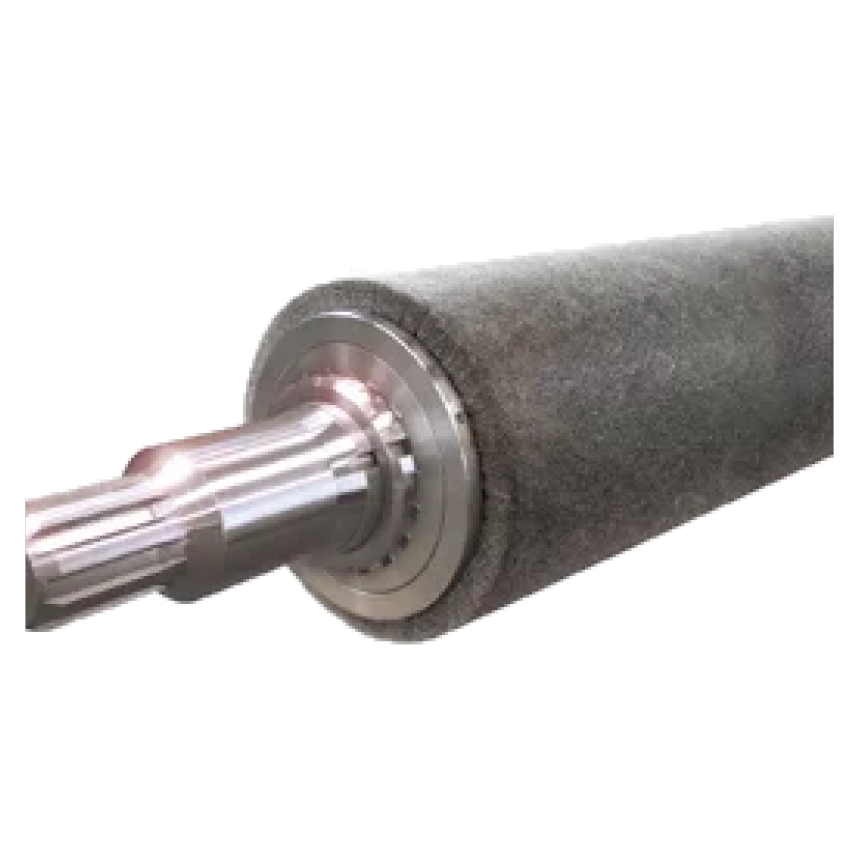

- Ball bearing disc springs are often used to distribute axial loads evenly in mechanical assemblies. The inclusion of a ball bearing allows for smooth rotation and reduced friction, enabling efficient load distribution.

- Ball bearing disc springs are used to preload bearings in various machinery. Preloading ensures that the bearings are always in contact, reducing play and improving the rigidity of the system.

Product features

Using Disc spring to preload radial ball bearings, helps to maintain positioning accuracy, eliminate shaft end play, and minimize vibration and shaft deflection by distributing the load evenly around the bearing race, extends the bearing life, eliminate excessive running noise. In most cases, the outer race of the ball bearing is preloaded with Disc Spring, and in some cases, it is desirable to preload the inner race of ball bearing.

Specifications

-

Kích thước:OD9.8-418 x ID6.2-272 x t0.2-4Vật liệu lò xo:60Si2Mn/DIN1.1.0909, 50CrV4/DIN1.8159Tiêu chuẩn:DIN1.1.0909, DIN1.8159

Related news

Products in the same group

Thư viện thông tin

84938 333 755

84938 333 755

Chat Zalo

Chat Zalo

Chat Messenger

Chat Messenger