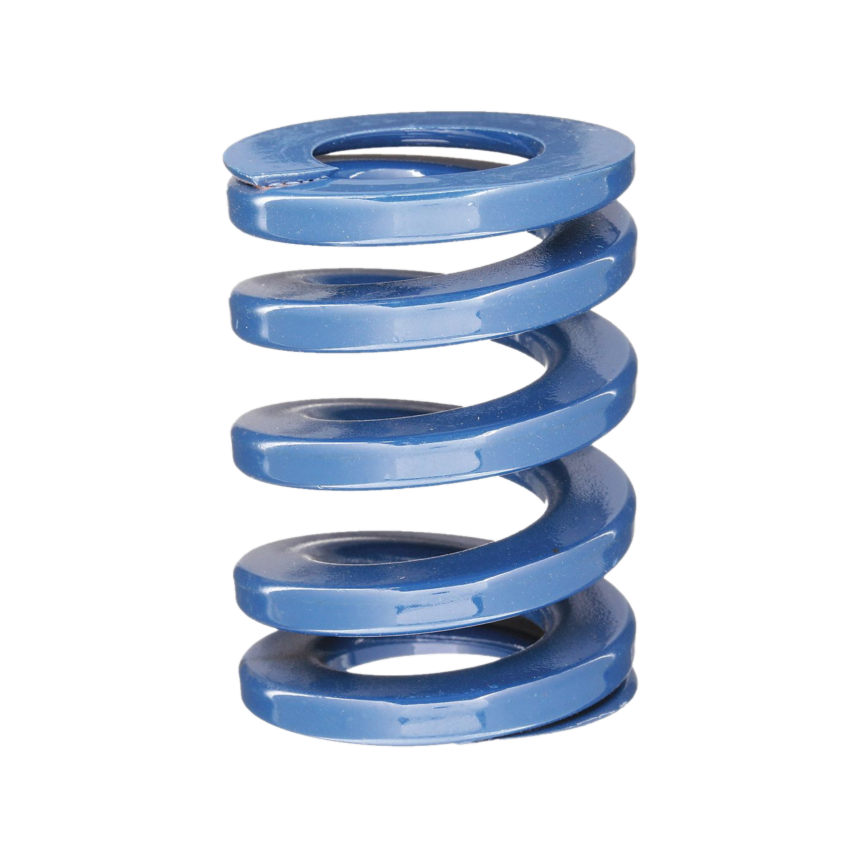

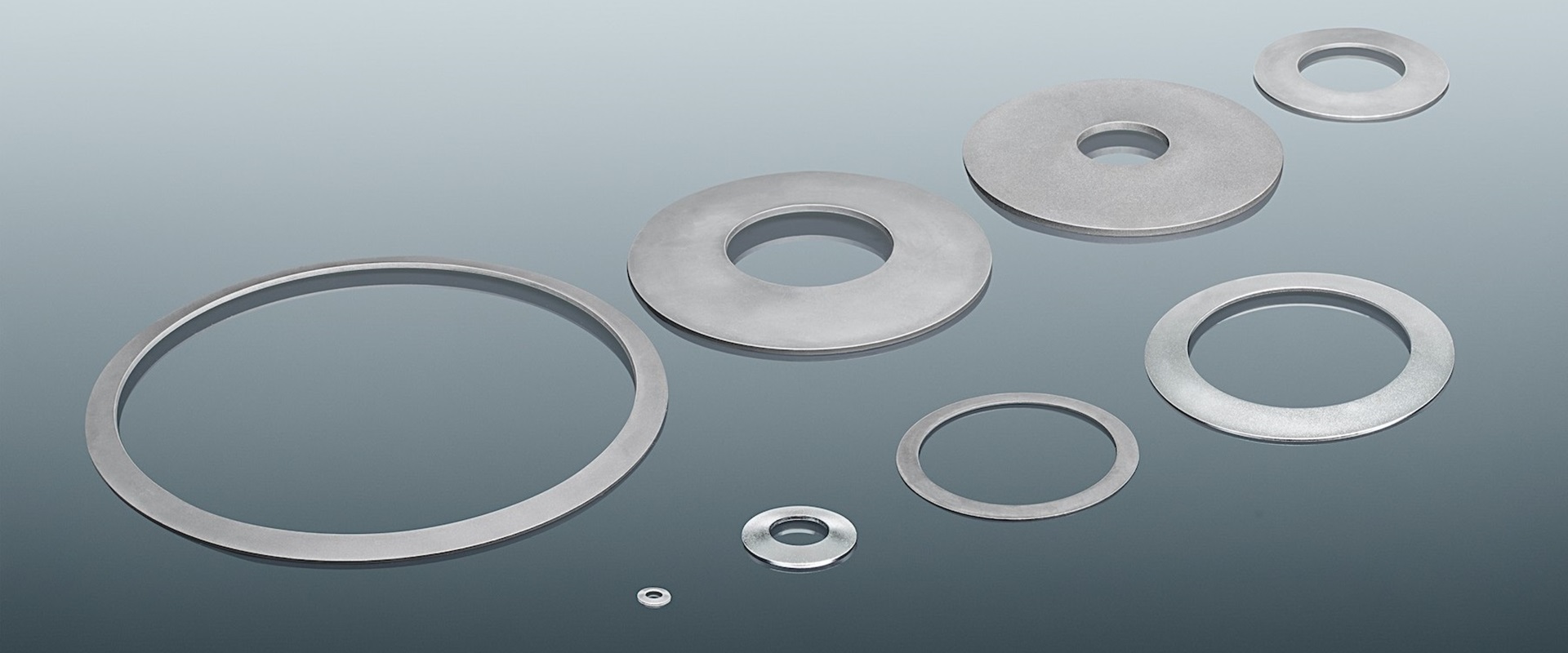

In the middle of the nineteenth century the conical shaped spring disc was invented. This spring disc was subsequently termed a “Belleville Washer” after the name of its inventor, Julian F. Belleville. In the 21st century, disc springs are used in endless devices such as spacecraft, satellites, medical devices, defence systems, automobiles and machine tools, to name a few.

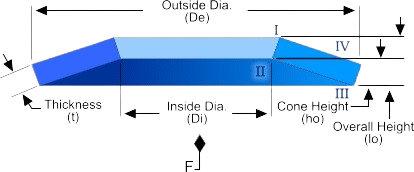

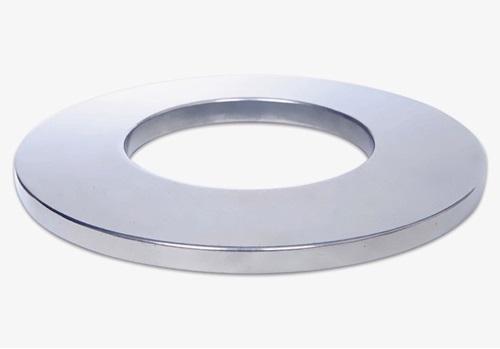

Disc springs are conical shaped washers designed to be loaded in the axial direction only… Disc springs can be statically loaded, either continuously or intermittently, or cyclically deflected i.e. dynamically loaded.

Buy using disc spring singularly or stacked in combinations variable spring characteristics can be achieved to suite a given application.

Application

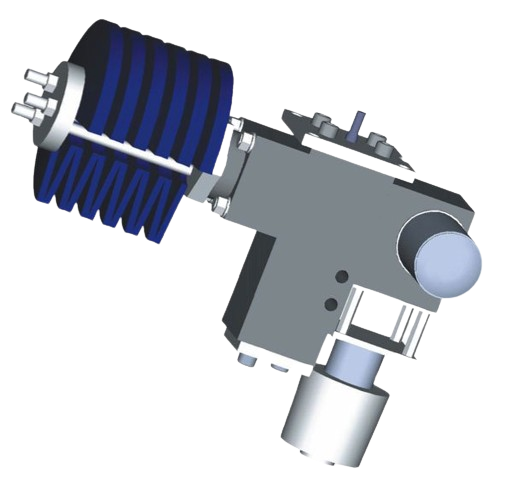

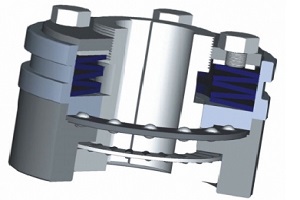

Mubea Belleville disc springs are used in a wide variety of applications across a broad range of industries. Belleville disc springs are primarily used in applications that require an extremely high amount of force over a small deflection. In many cases Belleville springs are used to replace coil springs where space is limited, a higher force is required, or the size of the system needs to be reduced.

Technology

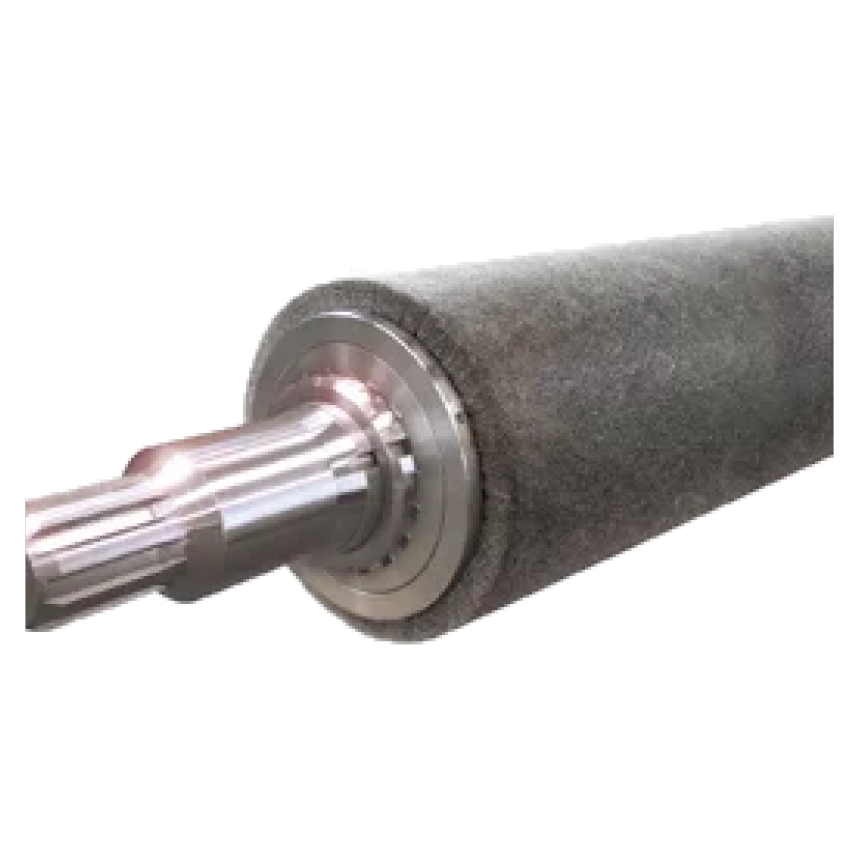

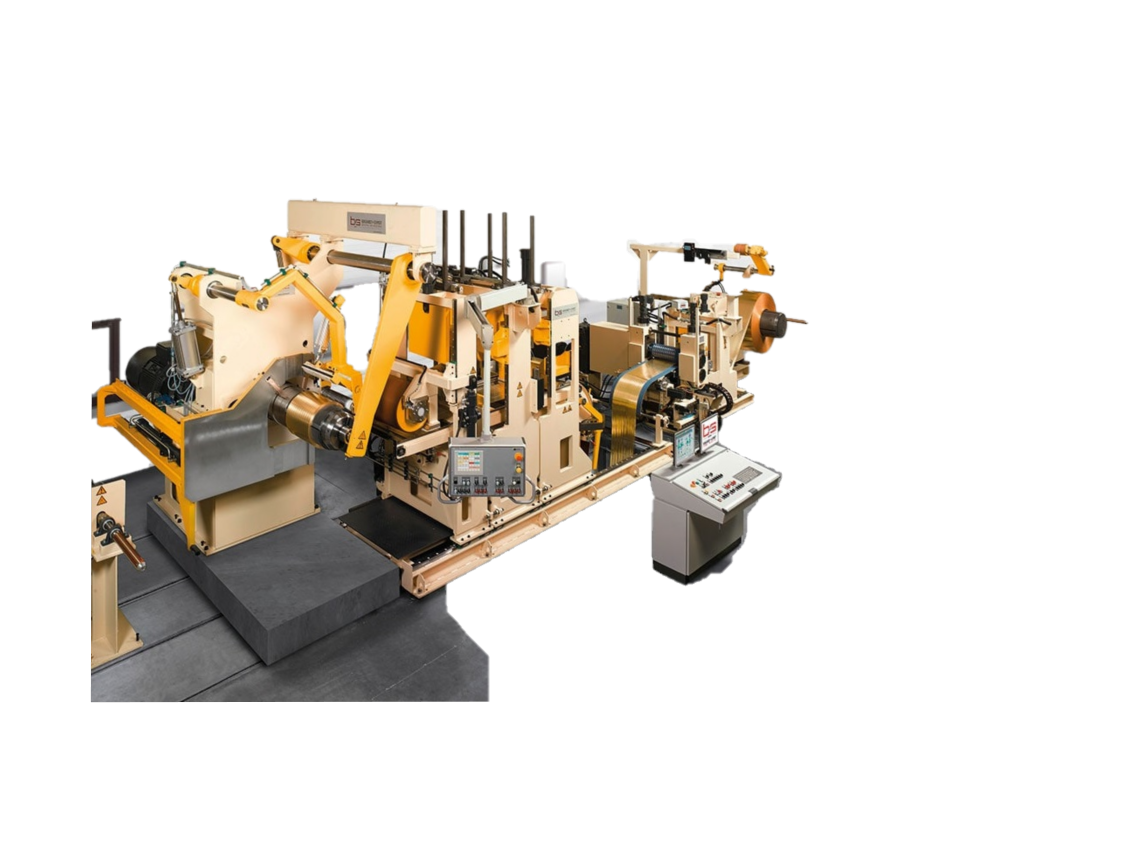

- In the manufacturing of Belleville disc springs, Mubea sets high internal standards to ensure superior quality at a reasonable cost by using innovative and extremely efficient production methods, starting with the production of the raw material.

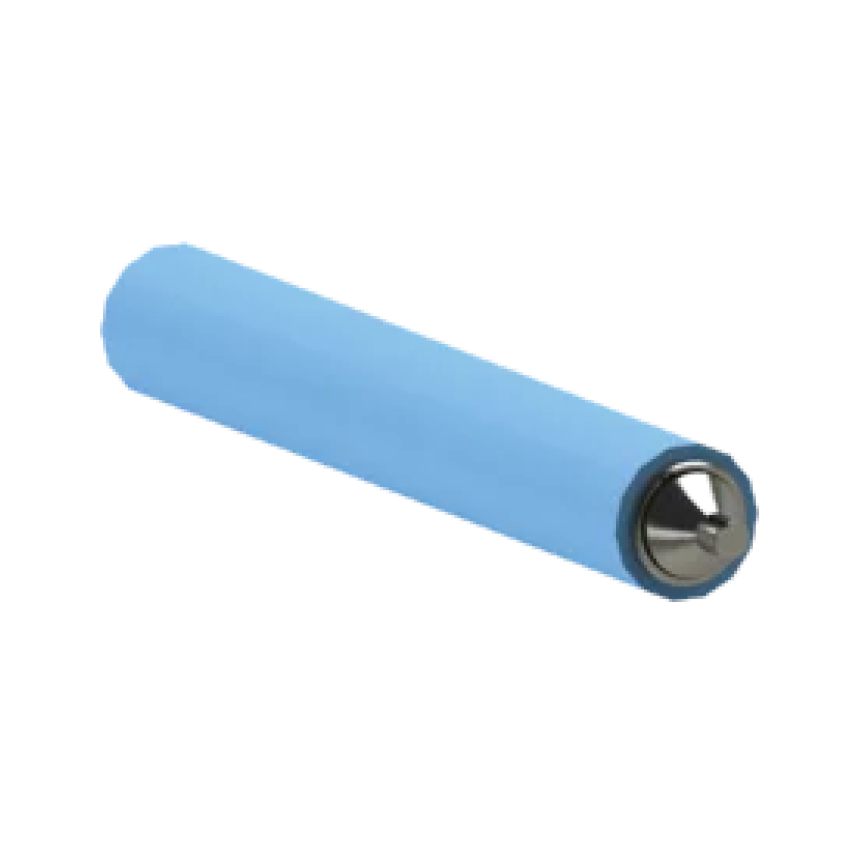

- The majority of strip material used is produced to very tight tolerances. Depending on the disc thickness, the disc blanks are manufactured by stamping (Group 1), fine blanking (Group 2) or plasma arc/flame cutting (Group 3). Disc springs of greater material thickness are machined all over to remove surface imperfections.

- Depending on the application, disc springs can be heat treated with either a martempering or austempering process to extremely tight hardness tolerances. Subsequent shot-peening improves the fatigue life of the springs. Our standard corrosion protection, phosphating and oiling, is done in our own facility. Complete monitoring of the various production stages guarantees the high quality of Mubea disc springs. Mubea’s quality system is certified to ISO/TS 16949 standards.

Classification

Disc spring following EN 16983 (DIN 2093)

Corrosion resistant disc spring

High Temperature disc spring

Slotted disc spring

Self-center disc spring

Stack dics spring

Specifications

-

Kích thước:OD6mm- 600mmVật liệu lò xo:51CrV4, X 10 CrNi 18 8 (DIN 1.4310), X 7 CrNiAl 17 7 (DIN 1.4568), X 5 Cr Ni Mo 18 10 (DIN 1.4401), Inconel 718, Inconel X 750Tiêu chuẩn:EN 16983 (DIN 2093), (DIN 1.4310), (DIN 1.4568), DIN2.4668, DIN2.4669

Contact info

-

Hotline hỗ trợ028 66 84 83 86

-

Thư viện media

-

Tư vấn mua hàng0938 333 755

Catalog

Related news

Products in the same group

Thư viện thông tin

84938 333 755

84938 333 755

Chat Zalo

Chat Zalo

Chat Messenger

Chat Messenger